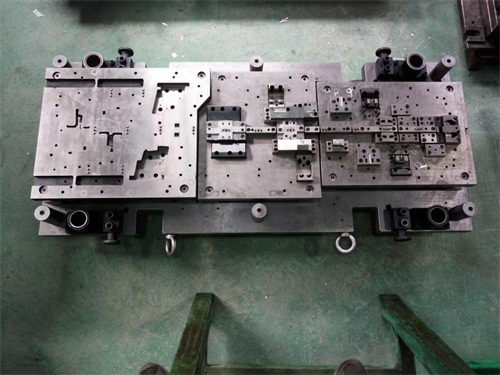

Progressive die stamping is one of metal forming methods that can encompass punching, coining, bending and several other ways of modifying metal raw material, combined with an automatic feeding system. Progressive die stamping consists of many individual stroke, each of them performs different operation on the progressive die stamping part.

The progressive stamping die is placed into a reciprocating stamping press. As the press moves up, the top die moves with it, which allows the material to feed. When the press moves down, the die closes and performs the stamping operation. With each stroke of the press, a completed part is removed from the die.

The feeding system pushes a strip of metal through all of the stations of a progressive stamping die. Each station performs one or more operations until a part is finished. The final station is a cut off operation, which separates the finished part from the carrying web. The carrying web, along with metal that is punched away in previous operations, is treated as scrap metal. Both are cut away, knocked down or out of the dies and then ejected from the die set, and in mass production are often transferred to scrap bins via underground scrap material conveyor belts.